Advantages to Pre-heating before welding

By David Rivas, Mechatronics Engineer and Informatics Technician

Much of the repair work made to a partially-damaged propeller includes the welding process; however, we would like to emphasize the importance of applying

heat before welding, to reduce post-weld damage.

Solder cracking and cracking at solder joints are common defects resulting from the absence of a pre-heating treatment when repairing a propeller.

Those problems can be avoided with a well-applied pre-heating treatment. Much of the repair work made to a partially-damaged propeller includes the welding process; however, we would like to emphasize the importance of applying

heat before welding, to reduce post-weld damage.

Solder cracking and cracking at solder joints are common defects resulting from the absence of a pre-heating treatment when repairing a propeller.

Those problems can be avoided with a well-applied pre-heating treatment.

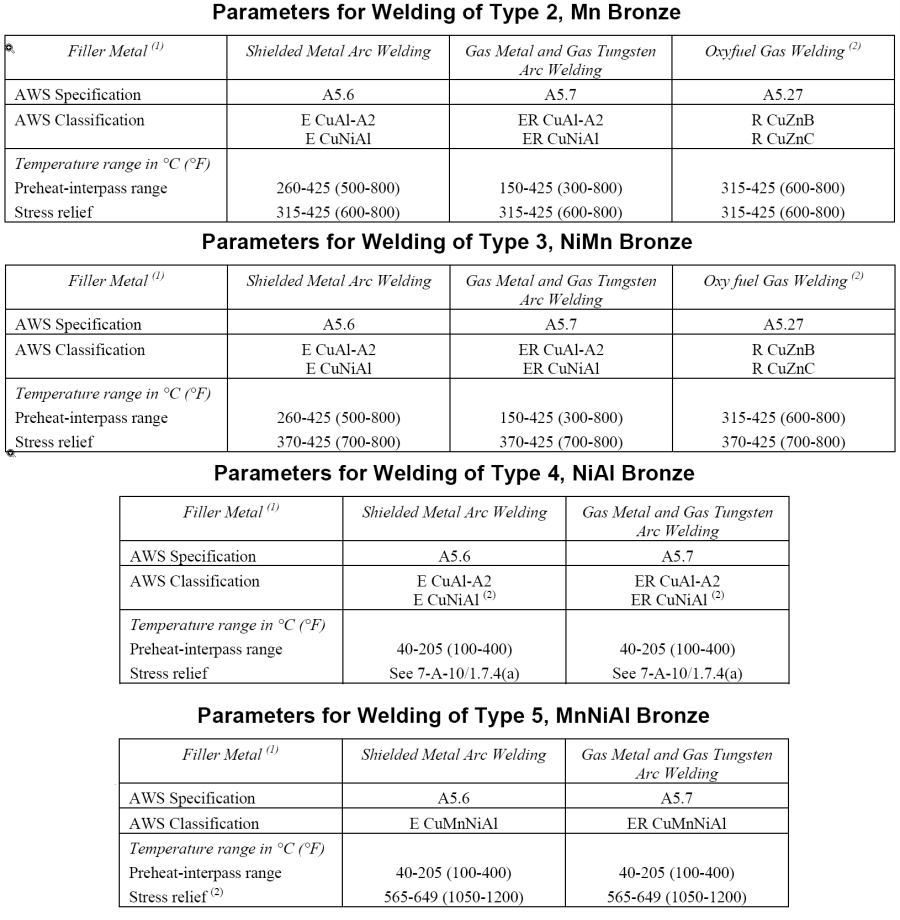

The pre-heating and interpass temperatures are to extend entirely throughout the section being repaired, covering a range of approximately 12 inches on

all sides of the repair area, so that a maximum temperature gradient of about 100°F per ft should be maintained in the surrounding area.

Heating is to be accomplished by means of soft gas (natural gas, LPG) torches, strip heaters, or by means of moving oxyacetylene torches used with proper

precaution, to avoid local overheating. The temperature is to be checked at frequent intervals by means of temperature indicating crayons or contact pyrometers. The pre-heating and interpass temperatures are to extend entirely throughout the section being repaired, covering a range of approximately 12 inches on

all sides of the repair area, so that a maximum temperature gradient of about 100°F per ft should be maintained in the surrounding area.

Heating is to be accomplished by means of soft gas (natural gas, LPG) torches, strip heaters, or by means of moving oxyacetylene torches used with proper

precaution, to avoid local overheating. The temperature is to be checked at frequent intervals by means of temperature indicating crayons or contact pyrometers.

|