How a Marine Nozzle Works

|

To obtain the most thrust, a

propeller must move as much water as possible in a given time. A nozzle will

assist the propeller in doing this, especially when a high thrust is needed at a

low ship speed. As we already know, as the propeller blades rotate in the water,

they generate high-pressure areas behind the each blade and low pressure areas

in front, and it is this pressure differential that provides the force to drive

the vessel. However, losses occur at the tip of each blade as water escapes from

the high pressure side of the blade to the low pressure side, resulting in

little benefit in terms of pushing the vessel forward. The presence of a close

fitting duct around the propeller reduces these loses by restricting water flow

to the propeller tips. |

|

|

The cross sectional area at the entrance of the nozzle is greater than

at the trailing throat. Since the water density is constant, the water

must accelerate from one to the other. Hence the water is already moving

faster as it reaches the propeller than it would on a conventional open

propeller. Therefore, more water is moved and more thrust created for the

same input power and torque.

However, there are efficiency gains to be

made even when it comes to the nozzle design. Some designs will drag as

the speed of the advance increases. With the Kort nozzle design, this drag

becomes more significant at higher speeds and can eventually reduce the

overall thrust gain to zero. The coefficient of drag is over 17 times less

with the Rice speed nozzle than the Kort 19A design. |

Rice Speed Nozzle Profile

Rice Thrust Nozzle Profile |

| The section of a Rice-Speed Nozzle

was developed from air wing sections displaying highest lift/lowest drag

properties. When nozzle sections of Kort 19-A and Rice-Speed are compared in

Figure 2 below, the drag coefficient of a Rice-Speed Nozzle is 17 times lower

than Kort 19-A type. |

|

| Figure 2. Comparison of Drag

Coefficient Between Kort and Rice Nozzles |

Kort Nozzle 19a cd = 0.17

|

Rice Nozzle cd = 0.01

|

OPERATIONAL ANALYSIS OF A RICE SPEED

NOZZLE

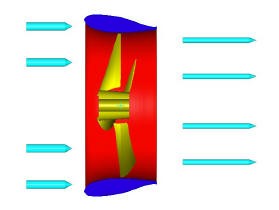

Figure 3 Transverse View of Rice Nozzle.

|

Due to the design (Figure 3), the propellerís working

area in the centre of nozzle, is approximately 40% smaller than the area

of the nozzle entrance. This results in an increase of water speed and a

decrease of internal pressure in relation with external pressure - which

remains more or less constant. Because of this pressure difference, a force

P (Figure 4) is created on the external surface of the nozzle that is

always perpendicular to this surface.

Due to the design of the outside trailing end part of the nozzle, the

horizontal component of this force P creates an additional forward thrust

on the nozzle; increasing the total thrust of the vessel. |

Figure 4 Pressure Differences Creates Additional Forward

Thrust.

Up to 40% of the total thrust is generated by the nozzle itself and is

transmitted directly to the hull.

|

|